The Growing Acceptance of CAD Jewelry Design

Anyone who’s even remotely astute toward the quickening of the evolution regarding 3D technology would most likely agree that CAD (Computer-Aided Design) is becoming a more prominent feature within the jewelry design industry. Most certainly, CAD Jewelry Design is such as feature that many contemporary designers are now beginning to grasp for a variety of reasons. Even though it takes a keen sense of craftsmanship to design jewelry of any form, there is no denying that even the most skilled jewelry designer needs very specific tools to manifest their vision. Both CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) are taking this fine and ancient trade to an entirely new plateau.

In its oldest form, not even spanning back a few decades ago, the general blueprint of creating jewelry commenced with; sketching the generalities, finalizing the layout with ink or a pencil, water-coloring the final design and then finally shifting over to the final construction process of it. The method of construction was widely known to be an obtuse process–that involved; carving the wax model, encasing it in a plaster casing and then, putting it in an oven. The wax will then melt out of the plaster casing, having the molten metal of choice (gold, silver, platinum, etc.) being poured in for the last step. Naturally, the recent introduction of CAD Jewelry Design greatly reduces this time-consuming process.

Even though the overall process is still the same designers can experiment, decide and finalize their pieces in half the time. This beautifully detailed ‘Frog Ring’ is just one of many examples of how effective CAD Jewelry Design can be without resorting to the traditional work method.

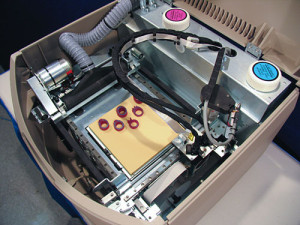

How CAD Jewelry Design is generally accomplished is that designers can garner photo-realistic conceptual art into their personal computer and mold their desired piece in a 3D environment. Colors, textures, metallic finishing and assorted jewels can be swapped out and experimented with. Discarded designs can be saved for future use. If needed, entire designs can be changed with a push of a button. Furthermore, resin models can be printed out through the use of CAM (Computer-Aided Manufacturing) machines if designers prefer the hands-on approach. Lastly, laser-sintering is the newest tool being used through the application of CAD Jewelry Design. It can be costly to acquire, but in the end, many designers find it to be worth it due to the fact that a general design can become a finished piece within a matter of hours. It can print a jewelry piece through a layering process with any chosen metal like; gold, silver, bronze or platinum within minutes.

The entire notion of 3D printing almost sounds too good to be true. However, truth can be stranger than fiction. The true beauty of jewelry design comes from the passion of the person who is forging the piece. With CAD Jewelry Design, that passion still emulates from the finished (xanax) product without the sacrifice of so many resources and time.

CAD Jewelry Designer

Igor Pinkevich

San Diego, CA 92129 USA

Phone: (858) 444-6308

Email: igor4d@gmail.com

Web: www.3dwaxcarving.com