How CAD jewelry design has revolutionized the jewelry making process

CAD jewelry design and CAM revolutionary technology are awesome innovations that have made a great impact on jewelry production process, making it totally different in the past few years. CAD (Computer-Aided Design) software and CAM (Computer-Aided Manufacturing) hardware, such as 3D printers are completely new tools that allow jewelry designers not only to achieve unparalleled precision and more realistic representation of the end product, but also to cut costs on some materials previously used in various finasteride stages of jewelry design and much more.

CAD jewelry design not only simplifies the process of jewelry creation, but also allows cutting the production time significantly. Before the advent of this amazing technology, designers had to use hand-drawn sketches of jewelry pieces, which they later rendered into a drawing made with pen, pencil or a watercolor paint. Then the delicate work of handcrafting out of metal or wax casting of a model needed to be done. These technologies have been used since ancient times and involve many steps and skilled manual labor.

Traditionally, a hollow wax model of a jewelry object was encased in a plaster mold and placed in an oven. Then, the wax melted and burned away, leaving a cavity, which was then filled through the hole with the molten precious metal. Once cold, the plaster was broken revealing the finished piece of jewelry.

CAD (Computer-Aided Design)

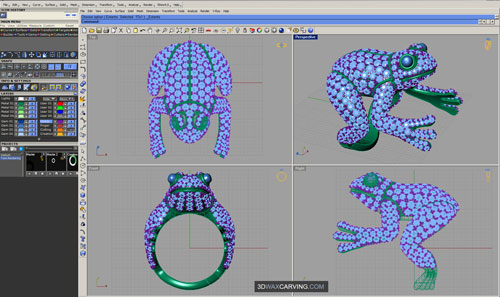

CAD software is used much for the design today’s jewelry. The versatility of CAD allows to make various design themes, functional or design elements that can be saved in a library and applied to different projects making the whole design experience faster and easier than if drawn by hand.

However, jewelry design process still involves many stages and requires special engineering skills, particularly when designing and producing high-end jewelry pieces. In spite of innovative CAD software and CAM hardware technologies, jewelry designers need to learn many things, such as gemstone setting methods to know different gem setting styles and other nuances. Nevertheless, these new technological advances have fundamentally changed the whole process of jewelry design and production.

CAD software is especially useful when it comes to designing complex jewelry pieces. Designers can zoom in to work with small areas to add fine and intricate details.

CAD also makes it easy for jewelry designers to experiment and let their creative imagination and inspiration fly. With “undo” options the elements that don’t fit in the design can be easily removed and replaced. Designers do not have to start from scratch all the time and can work by “trial and error” method to achieve the desired end results.

CAD gives a great opportunity of 3D rendering (with added shadows and reflections) of jewelry pieces that look very realistic and can even fool an expert’s eye. This helps in the presentation of jewelry pieces to individual or corporate clients allowing them to take a close look on how the finished jewelry product will look like.

CAM (Computer-Aided Manufacturing) and 3D Printers

CAD software also allows making several variations of one model. 3D Printing/Rapid Prototyping process helps easily create resin prototypes on CAM hardware such as 3D printer. In the past making variations was a cumbersome process that required using more than one rubber molds to make duplicates each time a new detail was added or a change was made. With new technology this can be made faster and easier – just with clicks of a mouse.

Jewelry CAD Design & 3D Modeling Services

Email: igor4d@gmail.com

Phone: 858-444-6308

San Diego, CA 92129

www.3dwaxcarving.com